Introduction

In modern substation protection systems, ensuring that circuit breakers operate reliably when needed is paramount. One critical component that guarantees this reliability is the Trip circuit supervision relay (TCS). This protective device continuously monitors the health of circuit breaker trip coils, preventing catastrophic failures before they occur.

In this comprehensive guide, we’ll explore what trip circuit supervision relays are, how they work, and most importantly—how to test them properly to maintain optimal protection system performance.

What is a Trip Circuit Supervision Relay?

A Trip circuit supervision relay (TCS) is an intelligent monitoring device that continuously evaluates the integrity of circuit breaker trip circuits. Think of it as a “health monitor” for your breaker’s trip coil, constantly checking that the circuit is ready to operate when a protection relay demands it.

Key Functions of TCS Relay

The supervision relay continuously monitors for several critical fault conditions:

- Open circuits – Broken wiring or disconnected trip coil connections

- Short circuits – Insulation failure within the trip coil

- Loss of power supply – DC supply failure to the trip circuit

- High resistance – Degraded connections or coil deterioration

When any fault is detected, the relay raises an alarm and provides visual indication (typically a flashing red LED), allowing maintenance personnel to address issues before they compromise system protection.

How Trip circuit supervision relay (TCS) Works

Operating Principle

The TCSR operates by injecting a small sensing current through the trip circuit when the breaker is in its normal closed position. This current is carefully designed to be too small to trip the breaker but sufficient to detect circuit integrity.

Let’s examine the three operational states:

1. Pre-Close Condition (Breaker Open)

Before the circuit breaker closes, the trip circuit supervision relay monitors the circuit through contacts TS1, TS2, and the breaker’s auxiliary contacts (52b). In this state:

- The sensing current flows through the complete circuit

- A flashing green LED indicates healthy condition

- The relay is actively supervising circuit continuity

2. Post-Close Condition (Breaker Closed)

After the breaker closes successfully:

- Sensing current continues to flow through TS1, TS2, auxiliary contacts (52b), and the trip coil

- The circuit path changes as auxiliary contacts (52a and 52b) shift position

- The green LED continues flashing, confirming healthy supervision

- The relay is ready to detect any abnormalities

3. Latched-Trip Condition

When a trip command is issued:

- The latched trip contact closes

- Full trip current flows through the trip coil

- The breaker opens as designed

- After successful operation, the relay returns to supervision mode

Critical Testing Procedures for Trip Circuit Supervision Relays

Proper testing of TCSR is essential for maintaining protection system reliability. Here’s a detailed step-by-step testing procedure based on industry best practices.

Pre-Testing Safety Checklist

Before beginning any tests:

- ✓ Notify control room and operations personnel

- ✓ Review manufacturer’s documentation (Siemens 7PJ13 shown in example)

- ✓ Ensure backup protection is available

- ✓ Verify proper PPE and insulated tools

- ✓ Obtain necessary permits and clearances

- ✓ Document baseline readings

Test 1: Operational Function Test (Open Circuit Detection)

Objective: Verify the relay can detect an open circuit condition

Procedure:

- With the breaker in service, identify the voltage supply terminals (highlighted contact points in the circuit diagram)

- Remove connection to any contact point from the voltage supply terminals as shown in the circuit diagram

- This simulates an open circuit or broken wire condition

- Expected Result: The relay should immediately detect the unhealthy condition

- Visual Confirmation: The LED should change from flashing green to flashing red

- The drop-off contacts should issue a control command/alarm

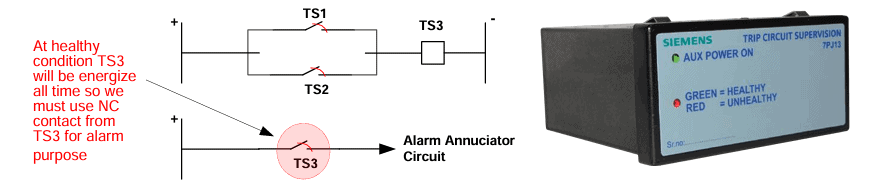

Important Note: For healthy operation, contact TS3 must remain normally closed (NC). Only use NC contact from TS3 for alarm purposes.

Test 2: Low Voltage System Verification

For DC 24V – 48V Systems:

The testing procedure requires a specific approach for low-voltage trip circuits:

- Short circuit test: Create a temporary short between pin numbers 1 and 4

- Expected Result: Relay should detect abnormal current flow

- Visual Indication: Red LED should flash, indicating unhealthy condition

- Alarm Verification: Check that alarm contacts operate correctly

Test 3: Sensing Current Measurement

Objective: Verify proper sensing current flow

Procedure:

- Using a precision ammeter, measure current through TS1 and TS2

- Normal Range: Typically 5-20 mA (refer to manufacturer specifications)

- Current should be consistent and stable

- Any fluctuation indicates potential circuit degradation

Test 4: Trip Circuit Continuity Test

Objective: Confirm complete circuit path integrity

Procedure:

- Trace current path through all components:

- Trip contact (Point 1 & 2)

- TS1 relay coil (Point 1, 2, 4, 5)

- TS2 relay coil (Point 4, 5)

- Auxiliary contacts 52a and 52b (Point 3)

- Trip coil (Point 6, 7)

- Return path (Point 8)

- Measure resistance at each section

- Compare with baseline values

- Any high resistance indicates connection degradation

Test 5: Auxiliary Contact Verification (52a/52b)

Objective: Ensure proper contact operation

The circuit breaker auxiliary contacts play a crucial role in supervision:

- Contact 52a: Closed when breaker is closed

- Contact 52b: Closed when breaker is open

Test Procedure:

- With breaker closed, verify 52b contact opens and 52a closes

- Manually operate breaker to open position

- Verify contacts reverse their states

- Check contact resistance (should be < 0.1 ohms when closed)

Test 6: LED Indication Verification

Visual Status Indicators:

- GREEN flashing = HEALTHY circuit condition

- RED flashing = UNHEALTHY circuit condition

- “POWER ON” indicator should be continuously lit when energized

Test each indication by simulating various fault conditions and verifying correct LED response.

Common Issues and Troubleshooting

Issue 1: False Alarms

Symptoms: Relay indicates unhealthy condition but circuit tests normal

Possible Causes:

- Relay sensitivity settings too tight

- High resistance in auxiliary contacts

- Voltage supply fluctuations

- Relay malfunction

Solution: Check settings, clean contacts, verify supply stability

Issue 2: Failed Detection

Symptoms: Relay doesn’t detect actual circuit faults

Possible Causes:

- Sensing current path compromised

- Relay power supply issues

- Internal relay failure

Solution: Verify power supply, test sensing circuit continuity, consider relay replacement

Issue 3: Intermittent Operation

Symptoms: LED flickers or alarm comes and goes

Possible Causes:

- Loose terminal connections

- Degraded auxiliary contacts

- Corroded wiring

Solution: Tighten all connections, replace worn contacts, inspect wiring

Best Practices for TCSR Maintenance

- Regular Testing Schedule: Test annually or per manufacturer recommendations

- Documentation: Maintain detailed test records with date, readings, and technician notes

- Trending: Track resistance and current readings over time to predict failures

- Contact Maintenance: Clean and inspect auxiliary contacts regularly

- Alarm Response: Investigate all TCSR alarms immediately—never ignore or bypass

Integration with Substation Protection Systems

Trip circuit supervision relays work in conjunction with various protection schemes. Understanding how they integrate with your overall protection philosophy is crucial:

- Differential Protection: TCSR ensures breaker availability for transformer or bus differential schemes

- Overcurrent Protection: Guarantees trip coil readiness for overcurrent relay operations

- Distance Protection: Critical for transmission line protection reliability

- Breaker Failure Protection: Provides early warning before breaker failure schemes activate

For more information on substation protection coordination, visit our Protection System Design Guide.

Recommended Testing Equipment

To perform comprehensive TCSR testing, you’ll need:

- Multimeter: For voltage and resistance measurements (Fluke 87V recommended)

- Clamp Meter: For sensing current measurement without circuit interruption

- Continuity Tester: For quick circuit verification

- Insulation Tester: For trip coil insulation checks (500V Megger)

- Stopwatch: For timing alarm response delays

Industry Standards and References

Trip circuit supervision testing should comply with:

- IEEE C37.234: Guide for Protective Relay Applications to Power System Buses

- IEC 62271-100: High-voltage switchgear and controlgear

- NFPA 70B: Recommended Practice for Electrical Equipment Maintenance

Always consult your facility’s specific standards and manufacturer guidelines.

Conclusion

Trip circuit supervision relays are an often-overlooked but absolutely critical component of substation protection systems. Regular, thorough testing ensures that when your protection relays issue a trip command, the circuit breaker will respond reliably.

By following the testing procedures outlined in this guide, you can identify potential failures before they compromise system protection, maintaining the highest levels of reliability and safety in your electrical infrastructure.

Remember: A supervision relay is only as good as its last test. Make TCSR testing a regular part of your maintenance program.

Related Articles

- Circuit Breaker Maintenance Best Practices

- DC Systems in Substations: Design and Testing

- Protection Relay Testing Procedures

Additional Resources

For more detailed information on substation equipment testing and fault analysis, explore our comprehensive resources at SubstationFaults.com.

External References: