In today’s world of electrical power, we need more efficient ways to transmit electricity over long distances. High-Voltage Direct Current (HVDC) is one of the most effective technologies for this job. Among all HVDC systems, the Line Commutated Converter (LCC) Classic system is the most trusted and widely used method for sending power efficiently across the globe.

Understanding HVDC systems becomes crucial when dealing with electrical substation faults and power transmission challenges that modern electrical engineers face daily.

Why Choose HVDC Over Regular AC Power?

HVDC has many advantages over traditional AC power transmission. First, it costs much less for long-distance power lines. DC power flows smoothly without constantly changing direction like AC power, which changes 50 or 60 times every second. This means HVDC has much lower energy losses.

For cables, especially underwater ones, HVDC is even better. Regular AC cables can only work effectively for about 50-100 kilometers because they waste energy through something called “charging current.” But HVDC cables have no distance limit and need only two cables instead of three. This makes underwater power connections much cheaper and more reliable.

The IEEE Power & Energy Society provides extensive research on power transmission technologies, highlighting HVDC’s superiority for long-distance applications.

How HVDC LCC Classic Systems Work

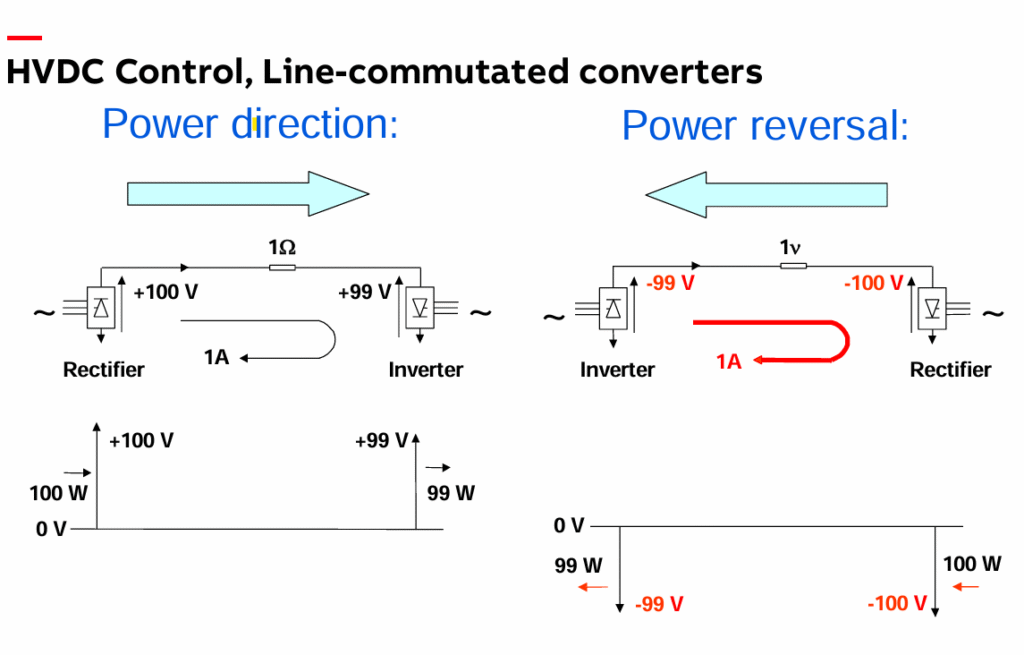

The HVDC LCC Classic system works in a special way that makes it different from newer systems. While modern Voltage Source Converter (VSC) systems change the direction of electric current to control power flow, LCC Classic does something smarter. It changes the voltage direction but keeps the current flowing in the same direction. This makes the system very strong and perfect for carrying large amounts of power.

The heart of every LCC Classic system is called a 12-pulse converter. Think of it like a sophisticated electrical switch made up of two smaller 6-pulse units working together. These units have special devices called thyristor valves that turn on and off at exactly the right times to change AC electricity into smooth DC electricity.

Understanding Thyristor Valves—The Key Components

Thyristor valves are like super-smart electrical switches that make HVDC possible. Each valve can do four important jobs:

- Connect AC electricity to DC electricity

- Carry very high electric currents safely

- Block dangerous high voltages from both directions

- Turn on when given a command and turn off automatically when current reaches zero

These valves are designed with smart cooling systems that use water to keep them from getting too hot. The best part is that you can replace individual thyristors without stopping the water cooling system, making maintenance much easier.

Similar to how electrical commissioning procedures ensure proper equipment installation, thyristor valve installation requires precise procedures and testing protocols. Major manufacturers like ABB and Siemens have developed advanced thyristor technologies for HVDC applications.

AC Filters—Cleaning Up the Electricity

One of the most important parts of any LCC system is the AC filter system. These filters do two jobs at once—they clean up electrical noise (called harmonics) and provide the extra power (reactive power) that the system needs.

There are several types of AC filters:

- Single-tuned filters that target specific electrical noise frequencies

- Double-tuned filters that can handle two different noise frequencies (like 11th and 13th harmonics)

- High-pass filters that block high-frequency electrical noise

- PLC filters that have special designs for power line communication

These filters automatically switch on and off as needed to keep the electricity clean and balanced. Understanding filter operation is crucial for preventing electrical substation faults that can affect power quality.

The International Electrotechnical Commission (IEC) sets standards for HVDC filter design and performance requirements.

DC Filters—Protecting Communication Systems

DC filters are used to prevent HVDC lines from interfering with nearby telephone lines, radio systems, and railway signals. When electricity flows through HVDC lines, it can create electrical noise that affects these communication systems.

There are two main types of electrical noise on DC lines:

- Pole mode harmonics—electrical noise that flows in opposite directions on the two main power lines

- Ground mode harmonics—electrical noise that flows in the same direction and returns through the ground

The good news is that DC filters are not needed for underground or underwater cables because these cables have natural shielding that blocks the electrical noise.

This concept relates to DC supply systems in substations, where proper isolation between DC circuits is essential for reliable operation.

Smart Control Systems with Multiple Safety Features

The control system is like the brain of every LCC Classic setup. It has several important parts:

Firing Control System: This controls exactly when each thyristor valve switches on. It uses a firing angle (called “alpha”) as the main control setting. The system calculates the perfect timing for each valve to ensure smooth operation.

Current Control Amplifier: This provides super-fast responses to keep the current at exactly the right level, even during electrical problems. It has almost zero error in steady conditions.

Emergency Power Control (EPC): This acts like a safety guard that doesn’t need feedback from operators. When serious problems happen (like power lines breaking or generators failing), it automatically adjusts power levels to prevent blackouts.

Control Pulse Generator: This converts the calculated timing into actual electrical signals that tell each thyristor valve when to switch on or off.

These control systems work together to prevent dangerous fault currents that could damage equipment or cause system-wide failures. Modern control systems use advanced software similar to ETAP and SKM analysis tools for fault current calculations and protection coordination.

Reactive Power Management—Balancing the System

One tricky part of LCC Classic systems is managing reactive power. These converters need extra electrical energy (called reactive power) to work properly—about 50% to 60% of the main power they carry. This might seem like a problem, but engineers have found clever solutions.

The system uses harmonic filters and capacitor banks that automatically switch on and off to provide exactly the right amount of reactive power. When more power flows through the system, it needs more reactive power, so more filters automatically turn on. When power decreases, some filters turn off to keep everything balanced.

HVDC LCC Classic—Different Operating Modes:

HVDC LCC systems can work in three different ways:

Bipolar Operation: Uses two power lines with opposite electrical charges. This is the most common and efficient way because electrical noise from one line cancels out noise from the other line.

Monopole with Metallic Return: Uses one power line and one return wire made of metal.

Monopole with Ground Return: Uses one power line and the earth itself as the return path. This mode requires special electrode stations buried in the ground about 25-30 kilometers away from the main converter station.

Understanding these operating modes is essential for electrical substation design and helps prevent operational issues that could lead to system faults.

Grounding Systems—Multiple Layers of Safety

HVDC systems have two types of grounding for safety:

Station Grounding: This is a backup safety system that can handle small currents (20-30 amps) for short periods. It’s mainly used for testing and emergency reference during faults.

Electrode Grounding: This is the main grounding system located 25-30 kilometers away from the converter station. It can handle the full power current and is designed to work for many years. The distance is important to prevent electrical interference with the sensitive equipment at the main station.

Good for the Environment and Economy

LCC Classic systems are great for both the environment and saving money. They can send electricity over very long distances with much less energy loss compared to regular AC power lines. The system works like electrical walls between different power networks, so if one network has problems, it won’t affect others.

This protection feature, along with precise power control, makes LCC Classic systems perfect for:

- Connecting renewable energy sources like wind and solar farms

- Supporting weak electrical grids

- Connecting power systems in different countries

- Reducing environmental impact through fewer power lines

The International Energy Agency (IEA) reports that HVDC technology is crucial for integrating renewable energy sources and reducing global carbon emissions. Organizations like CIGRÉ continue to develop best practices for HVDC system implementation worldwide.

Conclusion: Proven Technology for the Future

HVDC LCC Classic systems represent many years of engineering improvements. They offer reliable performance for high-power, long-distance electricity transmission with sophisticated filtering systems, multiple safety controls, and flexible operating modes. Their smart control features, strong thyristor technology, and comprehensive protection systems make them the top choice for important power projects around the world.

Further Reading:

- Learn more about electrical substation faults and prevention

- Explore DC supply systems in electrical substations

- Understanding fault current analysis in power systems