Introduction

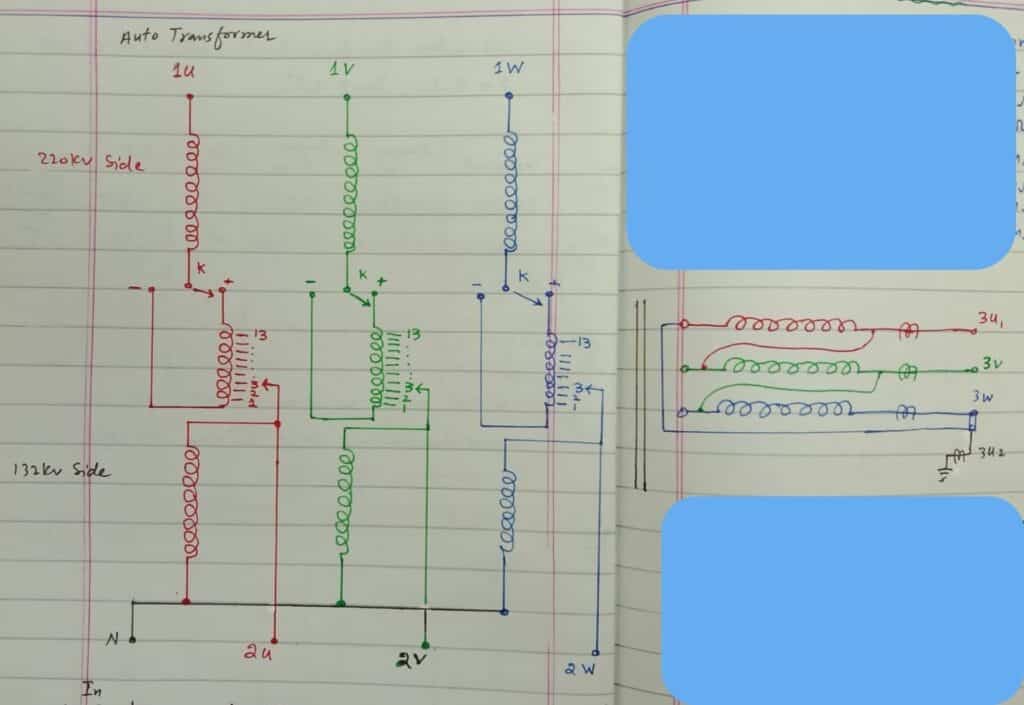

An Auto Transformer is a special type of electrical transformer used in power systems to change voltage levels. Unlike regular transformers that have separate coils for input and output, auto transformers use a single coil that does both jobs. This makes them cheaper, smaller, and more efficient for certain uses.

In this guide, we’ll explain everything about auto transformers in simple terms, so anyone can understand how they work and how to take care of them.

What is an Auto Transformer?

Simple Definition

Think of an Auto Transformer as a voltage adjuster. It takes electricity at one voltage level and changes it to another voltage level. The special thing about auto transformers is that they use one continuous wire coil instead of two separate coils like regular transformers.

How is it Different from Regular Transformers?

Regular Transformer:

- Has two separate coils (primary and secondary)

- Input and output are electrically separated

- Uses more copper wire and materials

- Larger and heavier

Auto Transformer:

- Has one shared coil

- Input and output are connected

- Uses less material (20-30% savings)

- Smaller and lighter

- More efficient

The main downside is that Auto Transformer don’t provide electrical isolation between input and output, which means they can’t be used in all situations.

Main Parts of an Auto Transformer

1. Tank and Cooling System

The Tank: The tank is like a strong metal container that holds everything. It’s made from carbon steel and designed to:

- Keep oil from leaking out

- Handle pressure changes

- Protect against corrosion

- Keep the transformer sealed

Cooling System: Transformers get hot when working, so they need cooling. There are different ways to cool them:

- Natural cooling: Oil moves naturally through radiators (like a car radiator)

- Forced cooling: Pumps move oil faster for better cooling

- Water cooling: Uses water to cool the oil in heat exchangers

- Air cooling: Fans blow air over radiators

The cooling method depends on how big the transformer is and how hard it works.

2. Oil Conservator (Oil Expansion Tank)

The oil conservator is like an overflow tank. It does four important jobs:

- Keeps oil level correct: When oil heats up, it expands (grows by about 0.8% for each degree). The conservator gives it room to expand

- Protects oil from air: Limits contact with air to prevent oil from going bad

- Keeps moisture out: Stops water from getting into the oil, which would ruin its insulating ability

- Houses safety devices: Contains equipment that detects problems inside the transformer

Air Breather: Connected to the conservator is an air breather filled with silica gel (small crystals that absorb moisture). The silica gel is usually blue or orange, but turns pink when it’s full of moisture. When 2/3 of it turns pink, you need to replace it.

3. Buchholz Relay (Gas Detector)

This is a safety device that watches for problems inside the transformer. It’s installed in the pipe between the tank and the conservator.

How it works:

- When something goes wrong inside the transformer, it creates gas

- The gas rises and gets trapped in the Buchholz relay

- Depending on how much gas and how fast it appears, the relay either sounds an alarm or shuts down the transformer

Two levels of protection:

Alarm – Goes off when:

- Oil is slowly leaking from the conservator

- Air gets into the cooling system (in pumped systems)

- Small amounts of gas form from minor problems

Trip (Emergency shutdown) – Activates when:

- There’s not enough oil

- Serious internal electrical breakdown creates lots of gas quickly

What to do:

- If alarm sounds: Disconnect transformer, find the cause, check for gas, fix the problem

- If trip activates: Don’t reconnect! Call the manufacturer for help

4. Bushings (High Voltage Connectors)

Bushings are special insulators that let high voltage wires pass safely through the metal tank. They look like tall porcelain towers on top of the transformer.

Two types:

- Regular bushings: Used up to 52 kV

- Capacitor bushings: Used above 36 kV (have special internal design)

Maintenance:

- Clean the porcelain every 2 months

- Check that connections are tight

- Look for cracks or damage

5. Tap Changers (Voltage Adjusters)

Tap changers let you adjust the output voltage. Think of them like a dimmer switch for lights, but for high voltage.

Two types:

Off-Circuit Tap Changer:

- Can only be adjusted when transformer is turned OFF

- Simpler and cheaper

- Used when voltage adjustments are rare

On-Load Tap Changer (OLTC):

- Can adjust voltage while transformer is running

- Uses a motor to change settings

- More complex but more flexible

- When first starting the transformer, set it to the highest voltage position

6. Thermometers and Temperature Monitors

These devices watch the temperature of:

- The oil

- The windings (coils inside)

If temperature gets too high, they:

- Sound an alarm (warning)

- Shut down the transformer (if it gets dangerous)

Regular checks needed:

- Compare with accurate thermometers every few months

- If readings seem wrong, calibrate or replace them

- Be careful not to bend the small tubes inside when checking

7. Pressure Relief Valve

This is like a safety valve on a pressure cooker. If pressure builds up too much inside the tank (from internal problems), this valve opens to release it and prevent an explosion.

What to check:

- The indicator should show it’s in the “rest” position

- If it trips, check for blocked air breather or internal problems

8. Oil Level Indicators

These show how much oil is in the tank and conservator. They have:

- Maximum alarm: Goes off if there’s too much oil

- Minimum alarm: Goes off if there’s too little oil

Common problems:

- Too much: Indicator broken, oil too hot, or someone overfilled it

- Too little: Indicator broken or there’s a leak

How to Maintain Your Auto Transformer

Every 2 Months – Quick Checks

- Air Breather: Look at the silica gel. If 2/3 is pink, replace it

- Pressure Relief Valve: Make sure indicator is at rest position

- Bushings: Clean the porcelain, check for tight connections

- Thermometers: Verify they’re reading correctly

- Oil Levels: Check for proper levels and look for leaks

- Cooling System: Make sure oil and water are flowing properly

- Control Boxes: Check motor units, lubricate hinges, remove insects or debris

Every Year – Detailed Inspection

- General Condition:

- In dusty areas, check if insulators, covers, and radiators are clean

- Clean dust from surfaces to prevent heating problems

- Thermometers and Gauges:

- Check condition and accuracy

- Reset or replace if needed

- Air Breather:

- Check silica gel condition

- Replace when more than 2/3 turns pink

- In tropical climates, check more often

- Protection Equipment:

- Test all relays (Buchholz, temperature, etc.)

- Check thermostats and their settings

- Test all external protection relays and adjust if needed

- For first startup, set overcurrent protection to 2-4 times normal current for 2 seconds

- Bushings:

- Clean thoroughly

- Check for cracks or damage

- Verify connections are tight

- Arcing Horns (if present):

- Check clearance, considering if surge arresters are installed

- If clearance exceeds 30 meters, consider additional surge protection

- Grounding:

- Check ground connections

- For non-fully insulated windings, neutrals must be grounded

- Full-insulation windings need surge arresters if not grounded

Every 2 Years – Oil Testing

Dielectric Strength Test: This tests how well the oil insulates (minimum 150 kV/cm).

Use standards like IEC 156 or GB7595. The oil must withstand certain voltages based on the transformer voltage:

For IEC 156 standard:

- Up to 70 kV transformers: oil must withstand 30 kV

- 70-170 kV transformers: oil must withstand 40 kV

- 170-245 kV transformers: oil must withstand 50 kV

- Above 245 kV transformers: oil must withstand 55 kV

Every 3 Years – Complete Testing

- Oil Chemistry:

- Test acidity (max 0.6 mg/gr)

- Test interfacial tension (minimum 15 dynes/cm)

- If transformer runs hot (above 75°C) for long periods, test more often

- Protection Systems:

- Complete test of all trips and alarms

- Follow each device’s instruction manual

- Tap Changer:

- Operate through entire range to verify smooth operation

- Internal Inspection (if needed):

- Required if you see signs of aging:

- Sludge or mud in oil

- Pieces of insulation in oil

- Combustible gas in Buchholz relay

- Abnormal noises from magnetic circuit

- Very low insulation resistance

- Changes in impedance voltage values

- Required if you see signs of aging:

Common Problems and Solutions

Problem 1: High Temperature Warning

Symptoms:

- Temperature alarm sounds

- Temperature indicator shows high reading

Possible Causes:

- Winding temperature increasing

- Cooling system not working

- Transformer overloaded for too long

What to Do:

- Write down the temperature

- Check if cooling system is working (pumps, fans, oil flow)

- Check if thermometer is accurate

- Reduce load if possible

- Fix cooling system if broken

Problem 2: Buchholz Relay Alarm

Symptoms:

- Buchholz relay alarm sounds (not full trip)

Possible Causes:

- Oil leaking from conservator

- Air getting into cooling system (forced circulation type)

- Small amount of gas forming from minor internal problem

What to Do:

- Disconnect the transformer from power

- Investigate all three possible causes

- Analyze any gas found (is it flammable?)

- If cause is (1) oil leak or (2) air entrance: Fix the problem, then you can reconnect

- If cause is (3) internal breakdown: Contact manufacturer – don’t reconnect on your own

Problem 3: Buchholz Relay Trip (Emergency Shutdown)

Symptoms:

- Transformer shuts down automatically

- Buchholz relay in trip position

Possible Causes:

- Not enough oil in system

- Serious internal electrical breakdown

What to Do:

- DO NOT try to restart the transformer

- Contact the manufacturer immediately

- Have experts analyze the problem before restarting

Problem 4: Oil Level Too High

Symptoms:

- Maximum oil level alarm

Possible Causes:

- Level indicator broken

- Oil temperature too high (thermal expansion)

- Someone added too much oil

What to Do:

- Check if level indicator is working correctly

- If oil level truly too high, safely remove some oil

Problem 5: Oil Level Too Low

Symptoms:

- Minimum oil level alarm

Possible Causes:

- Level indicator broken

- Oil leak somewhere in system

What to Do:

- Check if level indicator is working correctly

- Look for leaks (check all gaskets, valves, connections)

- Fix any leaks found

- Add oil to proper level

Problem 6: Cooling System Failure

Symptoms:

- Cooling not working

- Temperature rising

Possible Causes:

- Electrical circuit to cooling system broken

- Oil pump failed

- Water pump failed (in water-cooled systems)

- Motor-fans not running

What to Do:

- Check electrical power to cooling system

- Inspect pumps and motors

- Check for proper water or oil flow

- Replace broken motors or pumps

Problem 7: Control System Problems

Symptoms:

- Control circuits not working

Possible Causes:

- Relay broken

- No control voltage

What to Do:

- Check relays

- Verify control voltage is present

- Replace broken components

Problem 8: AC Supply Failure

Symptoms:

- Auxiliary systems not working

Possible Causes:

- Relay broken

- No AC voltage supply

What to Do:

- Check relays

- Verify AC power supply

- Replace broken components

Problem 9: Pressure Relief Valve Trips

Symptoms:

- Pressure relief valve activates

Possible Causes:

- Air breather blocked (check silica gel)

- Internal pressure from serious breakdown

What to Do:

- Check if valve is working correctly (see instruction manual)

- Check Buchholz relay operation

- Note (3): If Buchholz shows no alarm or trip, check breathing circuit, replace silica gel, and reconnect transformer

Problem 10: OLTC Protection Trip

Symptoms:

- On-Load Tap Changer protection activates

Possible Cause:

- Circuit breaker breakdown

What to Do:

- Write down OLTC position number and how many times it operated

- DO NOT reconnect

- Contact transformer manufacturer

Before Starting Your Auto Transformer – Important Checks

Before you turn on a Auto Transformer for the first time, or after maintenance, do these checks:

1. Check All Valves

Make sure:

- ✓ All radiator valves are OPEN

- ✓ Transformer-conservator connecting valves are OPEN

- ✓ Tap changer-conservator connecting valves are OPEN (if applicable)

- ✓ Sampling valves with blind flanges are CLOSED

2. Test the Oil Quality

The oil must be tested to ensure it can insulate properly. Use a “Megger” of at least 1000V.

Minimum acceptable values depend on voltage:

IEC 156 Standard:

| Auto Transformer Voltage | Oil Must Withstand |

|---|---|

| Up to 70 kV | 30 kV |

| 70-170 kV | 40 kV |

| 170-245 kV | 50 kV |

| Above 245 kV | 55 kV |

GB7595 Standard:

| Transformer Voltage | Oil Must Withstand |

|---|---|

| Up to 15 kV | 20 kV |

| 20-35 kV | 30 kV |

| 66-220 kV | 35 kV |

| Above 330 kV | 45 kV |

Compare test results with factory values. If values are too low, the oil needs treatment or replacement.

3. Check Conservator Oil Levels

Verify oil level in:

- Main transformer conservator

- Tap changer conservator (if equipped)

4. Test Insulation Resistance

With Auto Transformer OFF and completely disconnected:

- Test resistance between each winding and ground

- Minimum: 5 MΩ/kV for core-type transformers (at least 300 MΩ total)

- Temperature matters: Results must be adjusted if not tested at 20°C

Important notes:

- Bushing cleanliness affects results

- Devices connected in parallel affect results

- These factors can completely change measurements

5. Test Protection Systems

Check Buchholz Relay:

- Disconnect the transformer (switches OFF/open)

- Keep protection circuits ON

- Test alarm system using appropriate device

- Test trip system

- Clean relay

- Check that signals appear at control room

- Verify circuit breakers activate correctly

Check All Other Protection:

- Test all alarm and trip relays

- Verify thermometer readings are correct

- Check thermostat settings

- Test external protections (overcurrent, differential, etc.)

- For first startup: Set overcurrent to 2-4 × rated current, trip time about 1-2 seconds

- After startup: Adjust to normal settings

6. Clean and Inspect Bushings

- Clean all porcelain bushings thoroughly

- Check for cracks or damage

7. Check Clearances

- Verify clearance between live parts and ground

- Check if bushing connections are aligned properly and not stressed

8. Verify Grounding

Critical rules:

- Neutrals of non-full insulation windings MUST be grounded

- At least one point of windings must be grounded if not connected elsewhere

- For full-insulation windings: If neutral not grounded, must be protected by surge arresters

9. Final Safety Checks

Before energizing:

- Remove all tools and equipment from around transformer

- Keep all people away from transformer and control panels

- Verify tank ground connection

- Check fire protection system

- Verify all protection relays work properly

- Listen for abnormal noises when first energized

- Watch temperature rise with load

- Monitor transformer for several hours after startup

Transportation and Installation

How Auto Transformer are Shipped

Transformers can be shipped two ways:

1. Filled with Oil:

- Complete and ready to use

- All accessories installed

- Can start working immediately after delivery

2. Filled with Nitrogen Gas:

- Kept dry with pressurized nitrogen (0.3 kg/cm²)

- Must be filled with oil before use

- Oil must be treated and verified before filling

Parts Shipped Separately

Usually these items are removed for shipping:

- Conservator with pipes and accessories

- Tap changer motor units and shafts

- Electrical control cabinet

- Cooling system parts (radiators, pumps, pipes, fans)

- Bushings

The transformer oil is sent in separate sealed containers.

When Auto Transformer Arrives

Immediate checks:

- If nitrogen-filled: Check pressure (must be above 0.1 kg/cm²)

- Inspect all packages, especially those marked “FRAGILE”

- Look for any shipping damage

- Report damage immediately – may need special inspection

Storage Before Installation

If Oil-Filled:

- Store completely assembled with all accessories

- Keep filled with oil

- Keep air breather or nitrogen system connected

- Keep heating resistances ON in control boxes to prevent moisture

If Nitrogen-Filled:

- Keep nitrogen system operating

- Monitor pressure continuously

- Maintain overpressure (not exceeding 0.3 kg/cm²)

- Store for maximum 6 months

- If storage exceeds 6 months, equipment feeding nitrogen must be used

All Accessories (shipped separately):

- Store safely away from humidity and shock

- Special care for motor drive units and marshalling kiosks

- Keep them closed with heating resistances connected to avoid moisture

Assembly on Site

If transformer needs assembly, follow these rules:

Safety First:

- Prevent drops: Empty your pockets, secure all tools so nothing falls inside transformer

- Work quickly but safely: Especially when opening manholes or flanges

- Work in good conditions:

- Use covered area if possible

- Slightly heated environment

- Free from dust and humidity

- Have overhead crane available for heavy parts

- Keep it clean: Clean area to prevent dust from entering transformer

- Watch the weather: Don’t open transformer in rain, fog, or high humidity

Gasket Installation:

- Clean gasket surfaces with gasoline or acetone

- No grease or moisture allowed

- ALWAYS use brand new gaskets

- Never reuse old gaskets

Tightening Bolts Correctly:

| Bolt Size | Torque |

|---|---|

| M8 | 0.8 kg·m (8 N·m) |

| M10 | 1.5 kg·m (15 N·m) |

| M12 | 3.0 kg·m (30 N·m) |

| M16 | 5.0 kg·m (50 N·m) |

- Tighten in cross pattern (like tightening car wheel bolts)

- Stop when gasket compressed by 30% (flat gaskets) or 40% (O-rings)

Filling with Oil

Equipment Needed:

- Vacuum pump: flow ≥ 60 m³/h, vacuum < 1 mbar

- Oil filter unit: flow ≥ 2500 l/h, vacuum < 1 mbar, heating to 80°C max

Steps for Oil Filling:

Auto Transformer with Rubber Cell in Conservator:

- If conservator is not vacuum resistant, install the tank-conservator connection pipe first

- Connect OLTC and tank (if not already connected)

- Open all radiator valves

- Connect filter to lower sampling valve, verify oil sealed properly

- Heat oil to 70°C with system closed, take sample to test dielectric strength

- Fill oil maintaining temperature between 60-70°C

- Stop filling 100mm below vacuum plug (important: prevents pump damage)

- Keep vacuum for 4 more hours

- Prepare silica gel air breather

- Slowly return to normal pressure through silica gel

- Connect transformer-conservator pipe and finish filling

- Complete filling (assuming radiators already filled)

Auto Transformers without Rubber Cell: Similar procedure but connect filter to upper valve first, then follow manufacturer instructions.

Important Notes:

- Oil temperature during filling: 60-70°C

- Never let oil touch vacuum pump (will destroy it)

- Keep vacuum for 4 hours after filling reaches limit

- Return to atmospheric pressure SLOWLY through silica gel

- Make sure all radiators are filled

Installing Other Components

After oil filling, install:

- Motor-fans

- Thermometers

- Pressure gauges

- Marshalling kiosks

- Motor drive units

- All electrical connections for auxiliary circuits

Final Steps Before Starting

- Clean entire transformer carefully

- Remove any grease with gasoline

- Tighten all gaskets again (they may need re-tightening after settling)

- Look for any oil leaks

- If painting damaged: Clean, scrape, polish affected area, apply two paint layers (allow 24 hours between coats)

- Paint any touched screws or washers

Where Auto Transformers are Used

Common Applications

Power Distribution:

- Adjusting voltage in power lines

- Connecting different voltage networks

- Regulating voltage in substations

Industry:

- Starting large motors

- Matching voltage levels between equipment

- Laboratory testing equipment

Railways:

- Power supply for electric trains

Renewable Energy:

- Connecting solar farms to power grid

- Wind farm connections

Why Use Auto Transformers?

Advantages:

- 20-30% cheaper than regular transformers

- Smaller and lighter

- More efficient (less energy lost as heat)

- Better voltage control

- Lower operating costs

When NOT to Use:

- When you need electrical isolation between input and output

- When voltage change is very large (works best for small changes)

- When safety requires complete separation of circuits

Safety Tips

For Everyone

- Stay away from high voltage: Never touch or go near energized equipment

- Keep work area clear: Mark dangerous areas clearly

- Watch for oil: Report any oil leaks immediately

- Listen for unusual sounds: Strange noises may mean problems

- Follow warnings: Pay attention to all warning signs and labels

For Maintenance Workers

- Disconnect before working: Always turn OFF and verify no voltage before touching

- Use proper tools: Have insulated tools rated for the voltage

- Work in pairs: Never work alone on high voltage equipment

- Follow procedures: Don’t skip steps to save time

- Check weather: Don’t open transformer in bad weather

- Keep it clean: Cleanliness prevents many problems

- Document everything: Write down what you do and what you find

Fire Prevention

- Keep fire extinguishers nearby: Know where they are and how to use them

- Check for leaks regularly: Oil leaks can cause fires

- Maintain clearances: Keep space around transformer clear

- Inspect painting: Good paint prevents rust and degradation

- Emergency plan: Know what to do if fire occurs

Environmental Protection

- Contain oil leaks: Don’t let oil reach soil or water

- Dispose properly: Used oil and silica gel must be handled correctly

- Recycle materials: Many transformer parts can be recycled

- Reduce energy waste: Well-maintained transformers use less energy

Frequently Asked Questions

Q: How often should I check the silica gel? A: Every 2 months minimum. In tropical or humid climates, check monthly. Replace when 2/3 turns pink.

Q: Can I restart the transformer after Buchholz relay trips? A: NO! Never restart without finding and fixing the problem. Contact the manufacturer.

Q: What causes transformer overheating? A: Common causes include overload, cooling system failure, dirty radiators, low oil level, or internal problems.

Q: How long does oil last? A: With proper maintenance, oil can last many years. Test dielectric strength every 2 years and chemistry every 3 years.

Q: Can I do maintenance myself? A: Simple checks (visual inspection, silica gel, oil level) can be done by trained operators. Complex maintenance requires qualified technicians. Internal work requires specialists.

Q: What’s the most important maintenance task? A: Regular oil testing and keeping the cooling system working properly.

Q: How do I know if transformer is overloaded? A: Watch temperature indicators. If consistently running hot or alarms frequently, may be overloaded.

Q: What noise is normal? A: Low humming sound is normal. Loud buzzing, crackling, or banging is NOT normal – investigate immediately.

Q: How long can transformer be stored before installation? A: Oil-filled: indefinitely if properly maintained. Nitrogen-filled: up to 6 months with proper equipment.

Q: Do I need special training? A: YES! Working on high voltage equipment requires proper training and certification. Never work on equipment you’re not qualified for.

Conclusion

Auto transformers are efficient and economical devices for changing voltage levels in power systems. While they have many advantages over regular transformers, they also require proper understanding, regular maintenance, and careful operation.

Key Takeaways:

- Regular maintenance is essential – Follow the 2-month, yearly, 2-year, and 3-year schedules

- Oil quality matters – Test regularly and maintain proper levels

- Pay attention to alarms – They warn you before serious problems occur

- Safety first – Always follow proper procedures and safety rules

- When in doubt, ask – Contact the manufacturer for guidance on unusual situations

Remember: High voltage equipment is dangerous. Always respect it, follow procedures, and get proper training before working on transformers.

This guide provides general information based on industry standards. Always consult your specific transformer’s manual and follow local electrical codes and safety regulations.